Is your company struggling to contend with the challenges of transporting temperature-sensitive cargo? Given that even a small variation can lead to ruined goods, cold-chain fleets need to be aware of the trailer temperature at all times. Otherwise, vital loads like medicine and fresh produce could fail to reach their destinations unspoiled. The end result would hurt your bottom line and reputation, as well as deprive customers of crucial goods and necessities.

Though all types of cargo need some degree of care, temperature-sensitive loads require special attention. Important items such as pharmaceuticals and food products need to be carefully monitored to arrive at the end customer unspoiled. If the trailer temperature goes out of range, spoilage can occur and cause companies to potentially lose both money and customers.

Why is temperature monitoring important?

To address the challenges of cold-chain logistics and help companies grow their businesses, SmartTrack supports flexible temperature, humidity, and solutions to ensure service reliability and improve delivery management.

The consequences of temperature variations can be quite severe. Replacing spoilt goods can have a significant impact on the company’s profits. This increases costs and directly impacts profitability. If the cargo is something life-saving, such as vaccines, the impact could be even greater. To make matters worse, the end user will have to go longer without the delivery, which could lead to them choosing a different carrier in the future to avoid more disruptions.

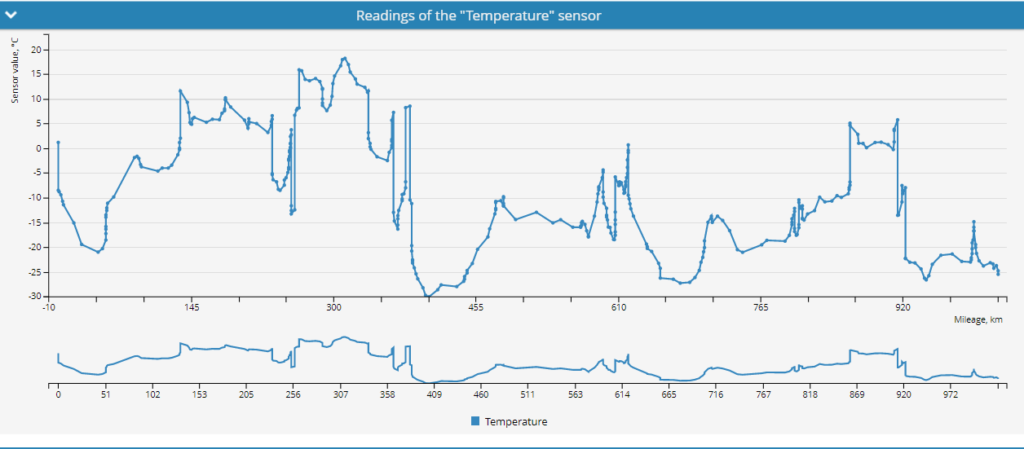

When combined, these problems can all lead to less business and lower profits for cold-chain fleets. SmartTrack’s cold-chain solution supports flexible alerts that warn managers when the temperature is out of range. This helps our customers retain their clients’ trust, avoid unnecessary product loss, and reliably deliver temperature-controlled cargo. Our platform also supports humidity monitoring to ensure proper moisture levels in the air, and door alerts to notify managers if a fridge door is open or breached.

Cold-chain partner success stories

One client was responsible for transporting chicken meat and eggs—products that must stay refrigerated to prevent spoilage. For dependably fresh deliveries, the company has sensors in their vehicles that utilize temperature monitoring with parameters out-of-range alerts. Thanks to this, they can know as soon as a variance occurs and take the proper action to avoid wasted products and loss of profits.

A produce transport company had to find a way to stop warm air from entering the reefer during inspections. This is to prevent loads of bananas from ripening before reaching their destination. By installing multiple sensors throughout the trailer, the company knows when the temperature is rising in certain areas. Additionally, regular reports assisted them with estimating how much product might spoil en route.

Ready to take the next step? If so, SmartTrack at 876-864-4181 or info@smarttrack.com.co to learn more about our modern cold-chain solutions.